Product Description

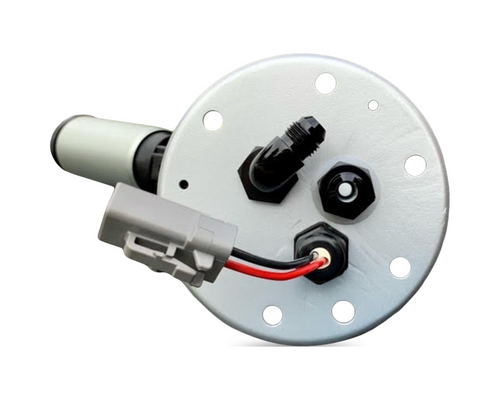

BKS1001 High Pressure, Brushless Fuel Pump & Controller Kit

which will replace the current BKS1000

Highly efficient current draw of less then 15A at 100PSI

This pump is great for E85, E10, any flex fuel and gasoline/petrol.

• Direct-fit replacement

• PWM (pulse-width modulation) input command controller

• High pressure, high flow E5LM brushless screw pump

• Support of 1,000+ horsepower

• Reduced system current draw

• Suitability for naturally aspirated and boosted applications

The BKS1001 has the added functionality of PWM control which we know enthusiasts want for their builds

BKS1001 has an optional speed control function. The controller will accept a pulse-width modulated input to slow down pump speed. This decreases fuel pump flow 350-370LPH from the maximum output. If this input is left disconnected

This kit includes many components including an E5LM submersible brushless fuel pump and controller. These two items are NOT available separately. The pump is an efficient screw pump design with positive displacement that is designed for in-tank installation only.

THE BRUSHLESS FUEL PUMP PERFORMANCE STANDARD

Brushless Pump Specifications:

• 550+ LPH @ 13.5V / 40 psi

• Capable up to 1000+ HP

• High flow, high pressure

• Reduced noise

• Suitable for both naturally aspirated and boosted applications

INPUT SIGNAL:

1. The controller requires a squarewave frequency (battery voltage to ground) at 100Hz.

2. When the duty cycle input is between 95-100%, the controller will output a 100% duty cycle signal to the pump.

3. When the duty cycle input is between 10-95%, the controller will output a linear transfer function though this range.

4. When the duty cycle input is less than 1-4%, the controller will output a 0% duty cycle signal to the pump.

5. When the signal wire is simply grounded, the controller will output a 45% duty cycle signal to the pump.

IN-TANK BRUSHLESS DESIGN PACKED WITH POWER

TI Automotive BKS1000 Brushless Pump and Controller Kit

TI Automotive’s new in-tank brushless fuel pump utilizes advanced technology for maximum reliability

and efficiency. The result is a next-generation pump for any type of engine offering precise control of fuel

pressure, lower current draw, reduced heat and less noise. Supporting up to 1000+ HP, the BKS1000

provides more power, more torque and more speed. Matched controller with simple power and ground

operations for easy maintainability. The controller features sealed electronics for weather resistance.

New brushless in-tank fuel pump kit, BKS1000 is capable of supporting up to 1000 HP, the kit includes TI Automotive’s in-tank brushless screw pump and a stand-alone pump controller with simple power and ground connectivity designed to provide optimal output of the in-tank screw pump. Included in the kit are an inlet filter, wiring harness, instruction sheet, and wiring diagram to assist with user installation. The BKS1000 kit has been designed, manufactured and tested to strict engineering standards.

Brushed DC motors have been around since the late 19th century and brushless motor technology has been around since the advent of solid state electronics in the 1960s. Yet, it wasn’t until the development of cheaper and higher powered transistor technology that brushless motors would find regular integration in nearly everything from cordless drills to computer fans. They’re also in fuel pumps manufactured by TI Automotive. What is the advantage of a brushless pump over a traditional brushed pump?

BRUSH VS. BRUSHLESS FUEL PUMPS

WHAT’S THE ADVANTAGE?

Advantage of Brushless Motor Technology in a Fuel Pump Integrating brushless technology with the latest fuel pump technology brings many advantages over brushed motor fuel pumps, including:

• Reduced noise due to less friction

• Helps provide a longer life due to less internal degradation

• Higher speeds through the use of magnetic induction without the restrictions caused by required direct contact of brushes

• Increased or decreased motor speed based on inputs from controller

• Can be tuned to required application